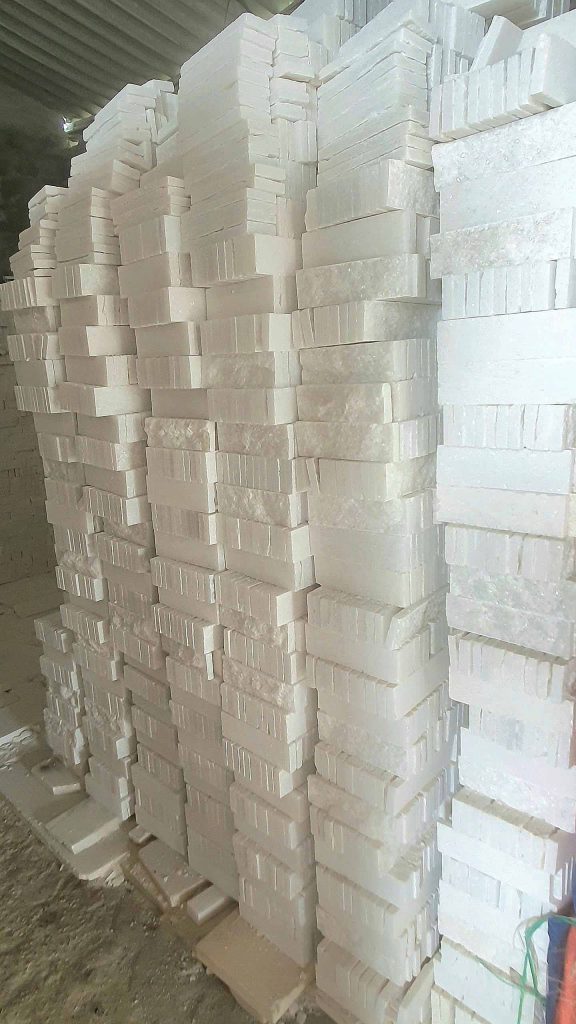

Manufacturing plant

Hoang Gia Mineral Group Jsc is a leading marble manufacturer in Vietnam, equipped with a state-of-the-art production system on a large scale: Sender Robots for automated material handling, Automatic Marble Polishing Machine Stations, Receiver Robots, Gang Saw machines with 80 blades…